Separation Technology Equipment’s

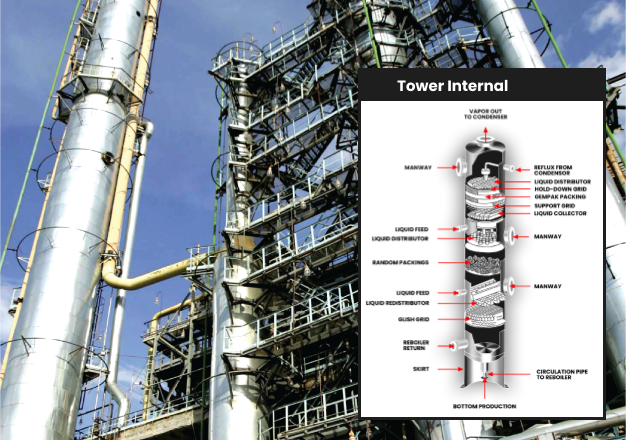

Column Internals

Column Internals are the devices that interact and separate, used in industrial columns. These columns use a variety of component to perform their job including Trays (at time referred to as plates) and Packing. A Tray is a chemical equipment used to carry out unit operations where it is necessary to transfer mass between a liquid phase and gas phase

Our company has been specialized in fabrication and supply of Column Internals for mass heat transfer services in refineries, petrochemical/chemical and gas processing plants. We are ready to supply every kind of Column Internals Parts for your emergency, regular, and new project installation requests.

Column Internals

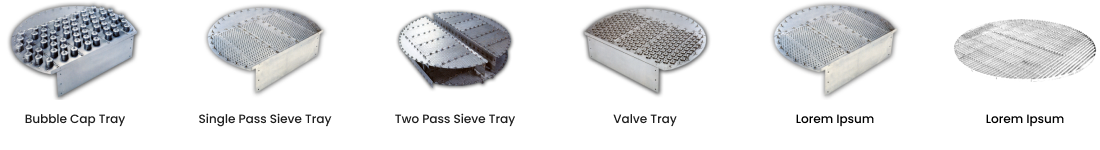

Valve Trays

Valve Trays

Valve Tray combine high capacity and excellent efeciency with a wide operating range. with these products advantages plus PT. Tuban Steel Works technical expertise in design, manufacturing, and installation, it’s no wonder our Valve Trays have been installed in tens of thousands of plants worlwide year after year, they continue to be the trays preferred by plant operators.

High Capacity Low Pressure Drop

Valve Tray can handle loadings up to 10% higer than sieve Trays while providing higer efficiency. The contoured hole of the T type Valve provides the lowest pressure drop per tray over a wide range of low rates.

Cost - Effective

Initial purchase price, simple installation, and reduced maintenance contribute to cost effective pro (ects when using valve trays).

Versatility

An exiting tower equiped with Valve Trays can often be used in different application with minimum

modifications due to the Trays’ wide operating range., high capacity, low pressure drop and excellent efficiency.

Tray for High Capacity

Process column revamps with high trays yield higher capacity with loss of efficiency. High capacity trays provide the solution to entrainment and down comer flooding problems that occur when throughput is increased in towers equipped with conventional trays. Operating data consistently demonstrates that high capacity tray out perform conventional valve or sieve trays, yielding up to a 30% increase in archived using a technologically advanced, patented design which employs the area under the down comer as tray active area.

.png)

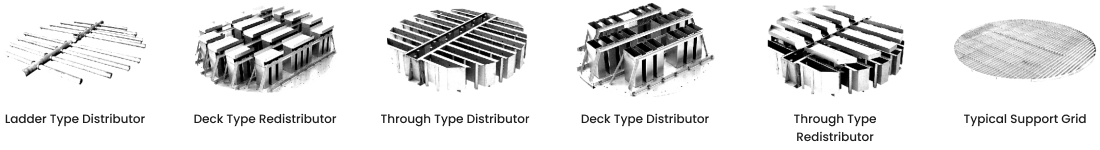

Packing

Generally, pressure vessel is a storage tank or vessel that has been designed to operate at pressure above 15 p.s.i.g, their main function is to balance and maintain a constant pressure in the water distribution system.

Random Packing

High efficiency good capacity moderate pressure drop good corrosion resistance quick delivery in emergencies. Random Packings and their accompanying special internal are available in carbon and stainless steels, nonferrous alloys, plastic and ceramics.

Typical Applications

- Absorbers

Co2 and H2S selective absorption Air pollution control scrubbers Ammonia absorption FCC absorbers. - Heat Transfer

DC / AC - Quench Columns

- Strippers

- Light ends Fractionators

EO /E4 Water deaeration and decarbonation Sour water strippers. - Degassing

- Liquid / Liquid Extraction

Demethanixers, Deethanizers.

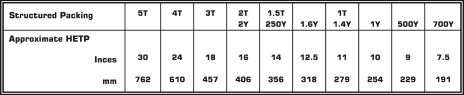

Structure Packing

HETP values are typical for total reflux distillation of low- alpha systems with good liquid and vapor distribution at moderate vacuum to moderate pressure in typical design range of 50% to 80% of food.